Ngwaahịa

Perforated ígwè warara PE ọkpọkọ Maka mmiri ọkọnọ

Ngwa

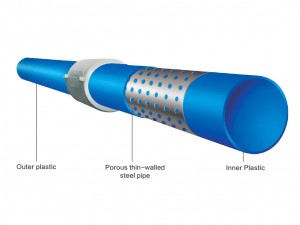

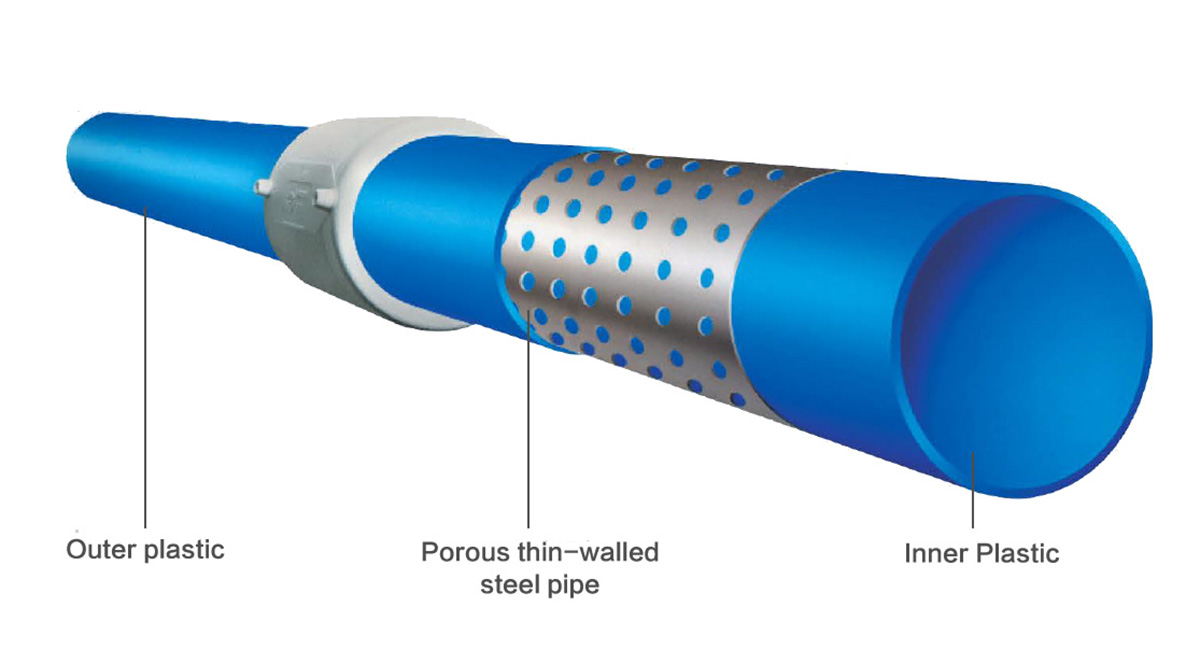

A na-eji ọkpọkọ ọkpọkọ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-eme ya dị ka akụrụngwa, yana ọkpọkọ ọkpọkọ nwere mgbidi siri ike nke argon arc butt welding ma ọ bụ ịgbado ọkụ plasma na-eme ka ọ bụrụ ihe mgbakwunye. N'ígwé nke mpụta na nke ime bụ thermoplastics mejupụtara akụkụ abụọ. A ọhụrụ ụdị nke composite mgbali ọkpọkọ, N'ihi na porous mkpa-walled ígwè ọkpọkọ mkwado na ọbọp na-aga n'ihu thermoplastic, a mejupụtara ọkpọkọ bụghị nanị na-emeri iche adịghị ike nke ígwè ọkpọkọ na plastic ọkpọkọ, kamakwa nwere rigidity nke ígwè ọkpọkọ na corrosion. iguzogide ọkpọkọ plastik. Ọ bụ ihe ngwọta maka mmanụ ala na ụlọ ọrụ kemịkalụ. Ọ bụ ọkpọkọ ọkpọkọ siri ike nke nnukwu na ọkara dayameta chọrọ ngwa ngwa n'ọhịa nke ọgwụ, nri, Ngwuputa, gas na mpaghara ndị ọzọ. Ọ bụkwa ọganihu nkà na ụzụ mgbanwe iji dozie isi pipeline nke ihe owuwu na mmiri ime obodo. Ọ bụ ụdị pipeline mejupụtara ọhụrụ na 21stnarị afọ.

Atụmatụ

Ike dị elu na mgbasawanye ahịrị dị ala.

N'ihi nkwado nke etiti nchara ahụ, ọkpọkọ ọkpọkọ ọkpọkọ ọkpọkọ na-agbapụta nchara nwere ike dị elu, nnukwu siri ike na nguzogide mmetụta karịa ọkpọkọ plastik. N'otu oge ahụ, mmetụta mgbochi nke nchara ígwè na-emekwa ka perforated ígwè warara plastic composite pipe pipe nwere а ala ahịrị yiri nke ígwè ọkpọkọ. Mgbasawanye ọnụọgụ na сгеер eguzogide.

Corrosion na iyi nguzogide.

Ihe polyethylene dị elu nke ahọpụtara maka ọkpọkọ ọkpọkọ ọkpọkọ, ihe na-abụghị polar polymer nwere ihe ndị nwere kemịkalụ kwụsiri ike, na-eguzogide ọtụtụ acid, alkali salts na organic media, yana corrosion electrochemical. Ọrụ egweri bụ ugboro 5 dị elu karịa nke ọkpọkọ ígwè.

Nka nka

Ngwaahịa a na-eji resin polyethylene pụrụ iche, yana akụrụngwa anụ ahụ na arụ ọrụ ya na-ezute ụkpụrụ Ministry of Construction Standard CJ/T181-2003 yana ọkọlọtọ ụlọ ọrụ kemịkalụ HG/T3706-2014.

| Nha nkọwapụta, ngbanwe na nrụgide aha: mezuo ihe achọrọ nke Ministry of Construction Standard CJ/T181-2003 | |||||

| N'ọnụ ọnụ elu dayameta na ndiiche | Ọkpụrụkpụ mgbidi ọnụ na iche | Site na okirikiri | Nrụgide aha | Uru S kacha nta | Ogologo na ndiiche |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.50 | 4.0 + 0.5 9 | 1.0 | 2.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5 + 0.6 0 | 1.26 | 2.0 | 1.5 | |

| 75+0.70 | 5.0 + 0.7 0 | 1.5 | 2.0 | 1.5 | |

| 90 + 0.9 0 | 5.5 + 0.8 0 | 1.8 | 2.0 | 1.5 | |

| 110+1.0 0 | 6.0 + 0.9 0 | 2.2 | 2.0 | 1.5 | |

| 140+1.1 0 | 8.0 + 1.0 0 | 2.8 | 1.6 | 2.5 | |

| 160+1.2 0 | 10.0 + 1.1 0 | 3.2 | 1.6 | 2.5 | |

| 200+1.3 0 | 11.0 + 1.2 0 | 4.0 | 1.6 | 2.5 | |

| 225+1.4 0 | 11.5+ 2.4 0 | 4.5 | 1.6 | 2.5 | |

| 250+1.4 0 | 12.0 + 1.3 0 | 5.0 | 1.6 | 3.5 | |

| 280+1.5 0 | 12.5+ 2.6 0 | 5.6 | 1.6 | 3.5 | |

| 315+1.6 0 | 13.0 + 1.4 0 | 6.3 | 1.25 | 3.5 | |

| 355+1.6 0 | 14.0 + 2.8 0 | 7.1 | 1.25 | 3.5 | |

| 400+1.6 0 | 15.0 + 1.5 0 | 8.0 | 1.25 | 3.5 | |

| 500+1.7 0 | 16.0 + 1.6 0 | 10.0 | 1.0 | 4.0 | |

| 630+1.8 0 | 17.0 + 1.7 0 | 12.3 | 1.0 | 4.0 | |

| Rịba ama: Nrụgide ọnụ nke ọkpọkọ ihe mejupụtara bụ nrụgide kachasị na-ekwe ka ọkpọkọ na-ebufe mmiri na 20 Celsius. Ọ bụrụ na ọnọdụ okpomọkụ gbanwere, a ga-edozi nrụgide na-arụ ọrụ dịka ọnụọgụ nrụgide okpomọkụ nke ihe dị iche iche si dị. S uru: ebe dị anya site na dayameta dị n'èzí nke nkwado na elu elu nke ọkpọkọ. | |||||

| Achọrọ ịrụ ọrụ anụ ahụ na igwe | ||

| Ihe oru ngo | Arụmọrụ | |

| Isi mgbanaka, KN/m2 | >8 | |

| Nnwale dị larịị | Agbajighị | |

| Mbelata ogologo oge (100 Celsius, na-echekwa 1h) | <0.3% | |

| Nnwale hydraulic | Okpomọkụ: 20°C; Oge: 1h; Nrụgide aha x2 | Agbajighị |

| Okpomọkụ: 80°C; Oge: 165h; Nrụgide: Nrụgide ọnụ x2x0.71 (ihe mbelata) | ||

| Nnwale nrụgide mgbawa | Okpomọkụ: 20°C, mgbawa nrụgide ≥ nominal mgbali x3.0 | Mgbawa |

| Oge ntinye oxidation (200 Celsius), min | ≥20 | |

| *Nguzogide ihu igwe* Nkwekọrịta nnabata nke ọkpọkọ≥3.5J/m2 Mgbe ike ịka nká | Nnwale hydraulic, ọnọdụ nnwale ahụ dị ka ihe 3 dị na tebụl a | Agbajighị |

| Nnwale nrụgide mgbawa, ọnọdụ ule bụ otu ihe dị na tebụl a | Ọ bụghị mgbawa | |

| Oge ntinye oxidation (200 Celsius), min | ≥10 | |

* Naanị maka ọkpọkọ ihe mejupụtara na-acha anụnụ anụnụ*