Ngwaahịa

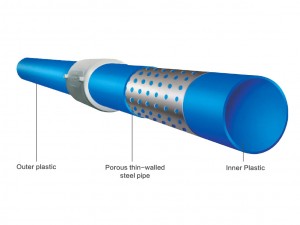

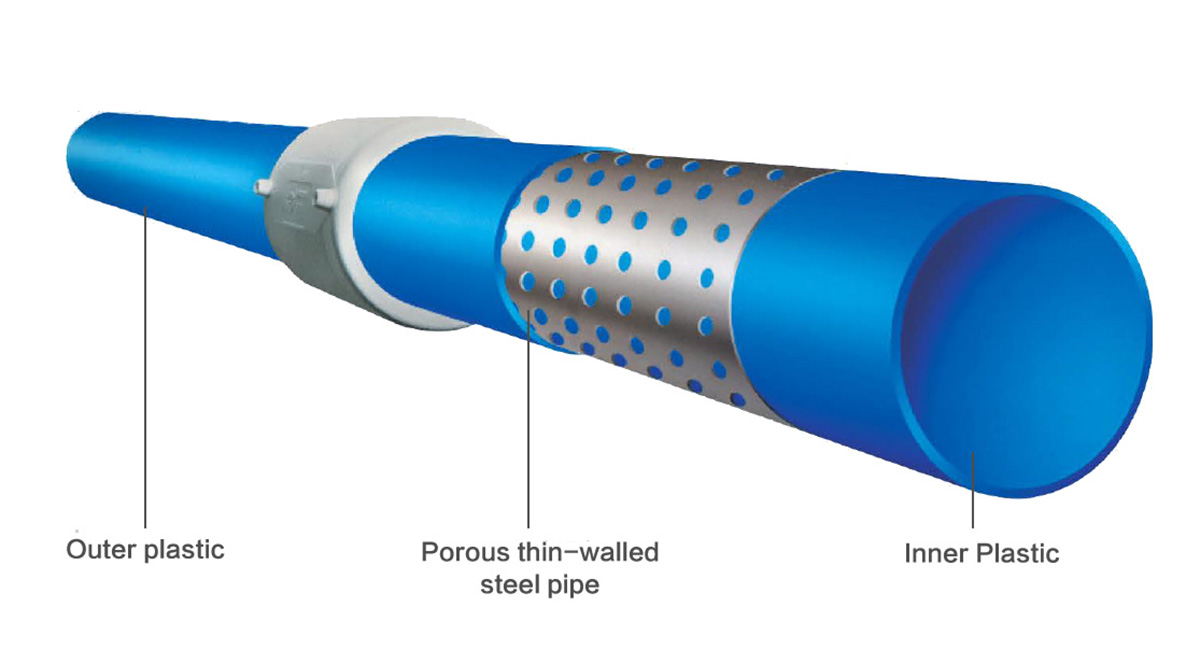

Perforated ígwè warara PE ọkpọkọ Maka gas

Ngwa

A na-eji ọkpọkọ ọkpọkọ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-eme ya dị ka akụrụngwa, yana ọkpọkọ ọkpọkọ nwere mgbidi siri ike nke argon arc butt welding ma ọ bụ ịgbado ọkụ plasma na-eme ka ọ bụrụ ihe mgbakwunye.N'ígwé nke mpụta na nke ime bụ thermoplastics mejupụtara akụkụ abụọ.A ọhụrụ ụdị nke composite mgbali ọkpọkọ, N'ihi na porous mkpa-walled ígwè ọkpọkọ mkwado na ọbọp na-aga n'ihu thermoplastic, a mejupụtara ọkpọkọ bụghị nanị na-emeri iche adịghị ike nke ígwè ọkpọkọ na plastic ọkpọkọ, kamakwa nwere rigidity nke ígwè ọkpọkọ na corrosion. iguzogide ọkpọkọ plastik.Ọ bụ ihe ngwọta maka mmanụ ala na ụlọ ọrụ kemịkalụ.Ọ bụ ọkpọkọ ọkpọkọ siri ike nke nnukwu na ọkara dayameta chọrọ ngwa ngwa n'ọhịa nke ọgwụ, nri, Ngwuputa, gas na mpaghara ndị ọzọ.Ọ bụkwa ọganihu nkà na ụzụ mgbanwe iji dozie isi pipeline nke ihe owuwu na mmiri ime obodo.Ọ bụ ụdị pipeline mejupụtara ọhụrụ na 21stnarị afọ.

Atụmatụ

Ọrụ ịdị ọcha

Ndekọ ịdị ọcha nke ịdị ọcha na nchekwa nke ọkpọkọ ọkpọkọ ọkpọkọ ọkpọkọ ọkpọkọ gbawara agbawa na-ezute ihe GB9687 “Hygienic Standard for Polyethylene Molded Products for Food Packaging” na GВ/Т17219 “Safety Evaluation Standard for Drinking Water Distribution Equipment and on Equipment and Protective Materials”. Ọ bụ ihe kacha mma dochie ọkpọkọ galvanized na nkedo ígwè.

Mgbidi dị n'ime na arụmọrụ mgbasa

Mgbidi dị n'ime nke nchara nchara eriri plastik mejupụtara ọkpọkọ dị ezigbo ụtọ, na enweghị ike zuru oke bụ naanị 1/20 nke ọkpọkọ ígwè.Ikike mbufe n'okpuru otu ọnọdụ dị ihe dịka 30% dị elu karịa nke ọkpọkọ ígwè.

Nka nka

| Nha nkọwapụta, ngbanwe na nrụgide aha: mezuo ihe achọrọ nke Ministry of Construction Standard CJ/T181-2003 | |||||

| N'ọnụ ọnụ elu dayameta na ndiiche | Ọkpụrụkpụ mgbidi ọnụ na iche | Site na okirikiri | Nrụgide aha | Uru S kacha nta | Ogologo na ndiiche |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.50 | 4.0 + 0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5 + 0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.70 | 5.0 + 0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90 + 0.9 0 | 5.5 + 0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0 + 0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0 + 1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0 + 1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0 + 1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0 + 1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0 + 1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0 + 1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0 + 1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0 + 1.7 0 | 12.3 | 0.6 | 4.0 | |

| Rịba ama: Nrụgide ọnụ nke ọkpọkọ ihe mejupụtara bụ nrụgide kachasị na-ekwe ka ọkpọkọ na-ebufe mmiri na 20 Celsius.Ọ bụrụ na ọnọdụ okpomọkụ gbanwere, a ga-edozi nrụgide na-arụ ọrụ dịka ọnụọgụ nrụgide okpomọkụ nke ihe dị iche iche si dị. S uru: ebe dị anya site na dayameta dị n'èzí nke nkwado na elu elu nke ọkpọkọ. | |||||

| Achọrọ ịrụ ọrụ anụ ahụ na igwe | ||

| Ihe oru ngo | Arụmọrụ | |

| Isi mgbanaka, KN/m2 | >8 | |

| Mbelata ogologo oge (110 Celsius, na-echekwa 1h) | <0.3% | |

| Nnwale hydraulic | Okpomọkụ: 20°C;Oge: 1h;Nrụgide aha x2 | Agbajighị |

| Okpomọkụ: 80°C;Oge: 165h;Nrụgide: Nrụgide ọnụ x2x0.71 (ihe mbelata) | ||

| Nnwale nrụgide mgbawa | Okpomọkụ: 20°C, mgbawa nrụgide≥nominal mgbali x3.0 | Mgbawa |

| Oge ntinye oxidation (200 Celsius), min | >20 | |

| Na-eguzogide mgbasawanye nrụgide ngwa ngwa (80°C, 4.0Mpa) / h | >1000 | |

| Nguzogide ihu igwe (mgbe ọkpọkọ natara≥3.5GJ/m2ike ịka nká) | Zute ihe achọrọ nke 2,3 na 4 na tebụl a, ma nwee ike ịnọgide na-arụ ọrụ ịgbado ọkụ dị mma | |